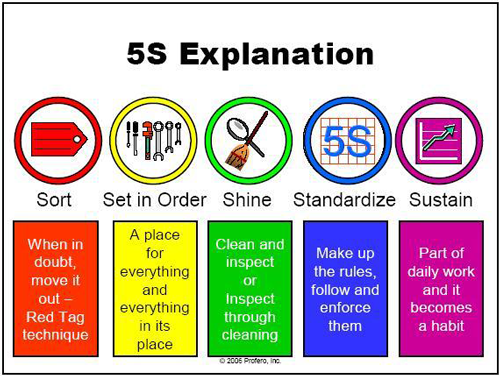

Kaizen 5s Program For Process Improvement | Presentation PowerPoint Diagrams | PPT Sample Presentations | PPT Infographics

5S Banners - We Are Committed To Continuous Improvement Sort; Set In Order; Shine; Standardize; Sustain (MBR099)

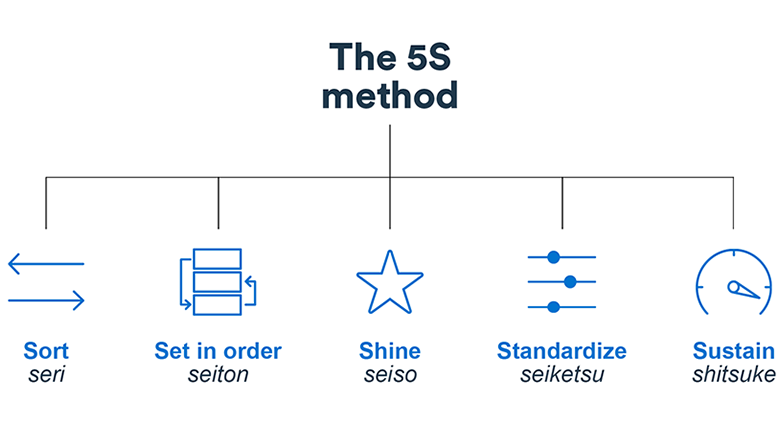

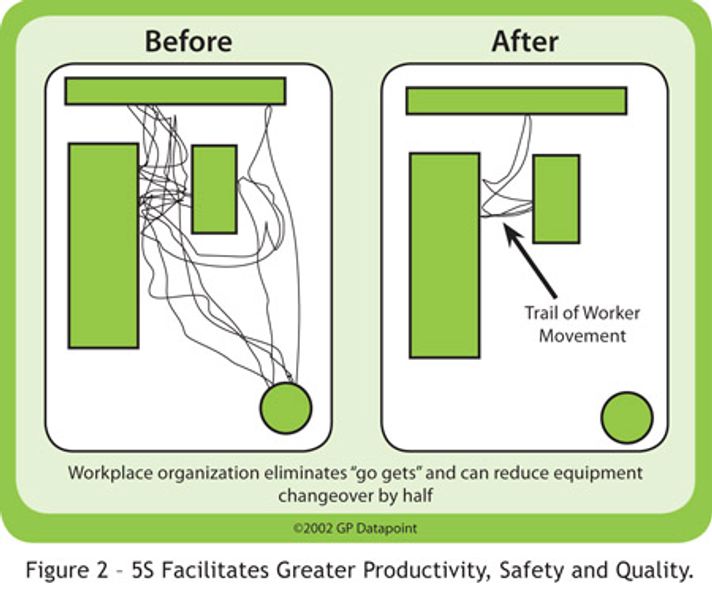

HARTAKITA on X: "The 5S practice is a method used to create a quality and productive workplace environment while establishing a passion for continuous improvement. As a result, the workplace and equipment

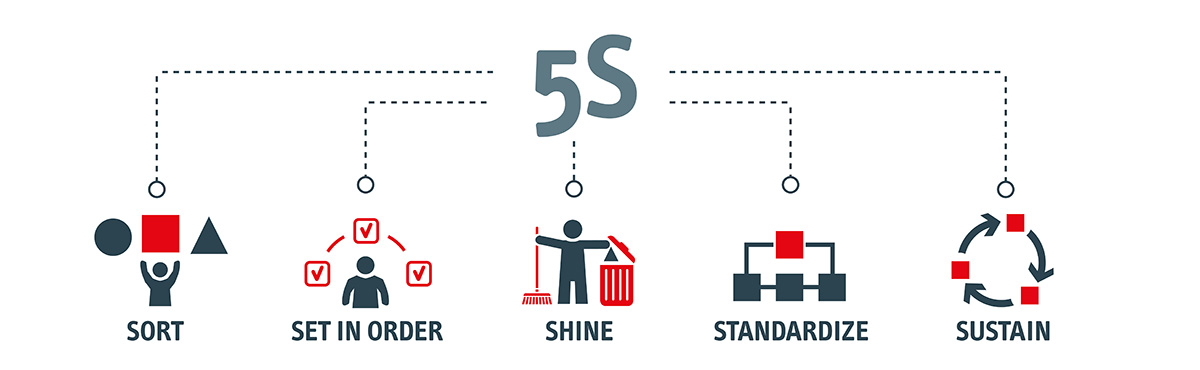

5S methodology cycle continuous improvement tool vector illustration Stock Vector Image & Art - Alamy

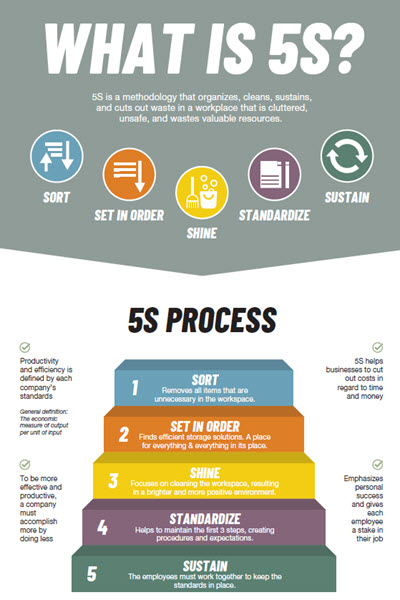

5S Continual improvement process Kaizen Organization Hunger, posters element, infographic, text, logo png | PNGWing